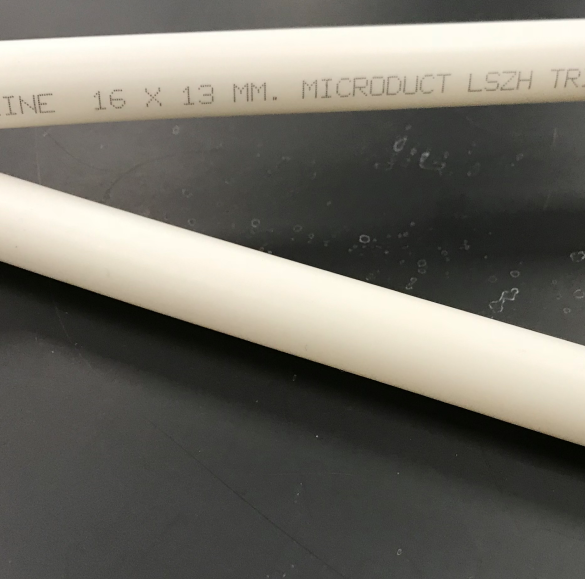

Dura-Line Releases a New Low Smoke Zero Halogen Family of Products

KNOXVILLE, TENN. – March 16, 2018 – Dura-Line is proud to announce the release of its newest innovative Conduit and MicroDucts made from a Low Smoke Zero Halogen (LSZH) material.

Manager of R&D/New Product Development, U.S., Thomas Chung, Ph.D., said, “Up until now, no one in the U.S. and Canada has truly perfected a finished product with both of these properties. We are the first to pioneer this technology and introduce it to the market.”

LSZH conduit and MicroDucts, ETL verified to UL1685-4 and IEC 60754-1, exhibit excellent properties such as low flame propagation, low smoke generation, zero halogen emissions, and excellent low temperature mechanical properties. They are designed for use in applications where smoke, toxic fumes, and acidic gas pose a health risk and possible damage to electronic equipment. Examples include enclosed public areas and poorly ventilated areas such as tunnels, mass transit corridors, behind-the-wall, control rooms, and confined spaces.

“Dura-Line is an industry leader and we have many customers that are looking for products like these,” said Tim Grimsley, Senior Vice President of Business Development, U.S. and Canada. “The market is starting to change, and customers are understanding they need a low smoke zero halogen solution. In many cases, it’s the smoke that harms people, not the fire.”

LSZH reduces risk and essentially allows more time to escape in the event of an emergency. Dura-Line has invested many years and significant resources in developing this cutting-edge technology to create a family of products that offer reduced smoke under high temperatures and zero halogen emissions.

“Other products produce toxic fumes when they burn,” Dr. Chung said. “Not to mention the risk to human life, and damage to the building and equipment. Millions of dollars can be lost because toxic fumes can ruin sensitive equipment like computer servers even if they don’t burn.”

Dr. Chung and his team discovered the proprietary formula using a systematic approach going through several formulations before finding the best mixture.

LSZH Conduit and MicroDucts from Dura-Line are leading the industry standards.

Dura-Line is an ISO-9001 rated manufacturer of HDPE conduits serving the telecommunications, enterprise, and electrical markets. Several advanced manufacturing techniques set us apart including low friction SILICORE™ permanently lubricated lining and FuturePath. FuturePath is a permanent pathway system for fiber optic cable with configurations for both outside plant as well as plenum, riser and low smoke halogen free (LSHF) for inside plant. With FuturePath in place, you can provide for rapid deployment of fiber with permanent pathways in place for future growth. Dura-Line has a team of engineers dedicated to training on use and installation techniques for our FuturePath products.

LSZH PRODUCT DETAILS:

- Standards:

- Conduit and MicroDucts are ETL verified to UL1685-4 and IEC 60754-1

- Size Range:

- Conduit Size Range: ½”, ¾”, 1” (additional sizes available in the coming months)

- MicroDuct Size Range: 5 mm OD (Outside Diameter) through 27 mm OD

- FuturePath* (factory pre-bundled with LSZH oversheath):

- MicroDuct Sizes: 5 mm OD through 27 mm OD

- Configurations: 2-, 3-, 4-, 7-, 12-, 19-, and 24-way (depending on MicroDuct size)

*FuturePath configurations have lower smoke properties and zero halogen emissions, but no U.S. specifications have been determined for this product type to date.

Thomas Chung

Thomas Chung, Ph.D., has over 20 years of experience in polymer processing and materials research. He joined Dura-Line from NuLabel Technologies in Providence, RI, where he was a Materials Program Manager. Prior to that, he worked for Fujifilm Electronic Materials in North Kingstown, RI, and Louisville, KY, as a Site Manager. Chung received his BS in Chemical Engineering from Han-Yang University in Seoul, Korea, and his M.S. and Ph.D. in Polymer Science from New York University, New York, NY.